Minimize Your Cost for Phased Array & TOFD

Third generation Phased Array flaw detector from SIUI, SyncScan incorporates the latest advancements in high performance Phased Array, TOFD, and high end thickness measurement functions into one compact unit.

SyncScan can minimize your cost for Phased Array and TOFD inspection

Superior Features

- High IP rate: IP65

- Light weight: 3.75 kg with battery

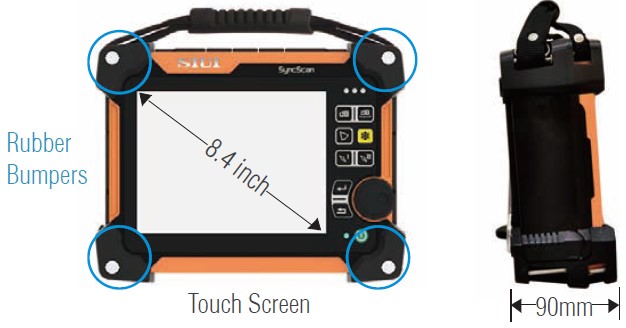

- Large touch screen: 8.4″ LCD with resolution 800×600 pixels

- Upgradeable from conventional UT to phased array, TOFD, thickness measurement with powerful & complete optional software functions

Compact and Durable

SyncScan is designed based on IP65 to suit the harshest industrial environment. Extra large 8.4 inch touch screen can bring optimized experience for measurement and reading.

SyncScan is so compact (3.75 kg, 90 mm thickness) that it can be operated with only one hand for aloft and field work

Conventional UT

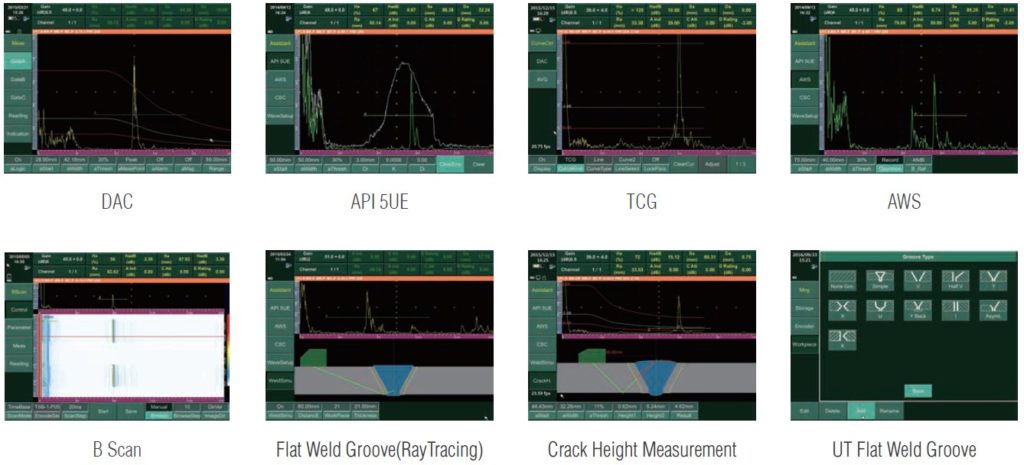

Basic Functions:

Velocity+Zero Calibration /

Angle Calibration / DAC / TCG / AVG (DGS) / Full screen A scan /

Coordinates switch (sound path, depth, horizontal) / Surface

compensation (xx+xxdB) / Auto freeze / Second leg color / Auto gain /

Wave compare / Wave filling

Advance Functions:

API / TCG / AWS / CSC / B Scan / Flat Weld Groove (RayTracing) / Crack Height Measurement / Probe Spectrum Analysis / Cineloop

Thickness Measurement

Advance function to achieve CoatTHK, Echo to Echo, B-Scan, V PATH, TDG, TEMP and MULTI-Layers Measurement.

Phased Array

Calibration Wizard

To facilitate phased array operators, SyncScan carries calibration wizard with step-by-step guide to maximize inspection speed.

PA Groups Function

One phased array probe can be designated up to six groups for different inspection, like sectorial or liner scan.

Multi groups of element and different angles can be applied for scanning at the same time, fully covering weld area and enhancing inspection efficiency.

Two phased array probes can work simultaneously to inspect both sides of weld, enhancing the inspection efficiency and speed.

BEA Function (Backwall Echo Attenuator)

This function is to help set a gate over an area and adjust the gain for this area regardless of the global gain. It is very useful for inspection of Forgings and Castings with allowing independent gain control of the area under the gate with the BEA for backwall echo monitoring.

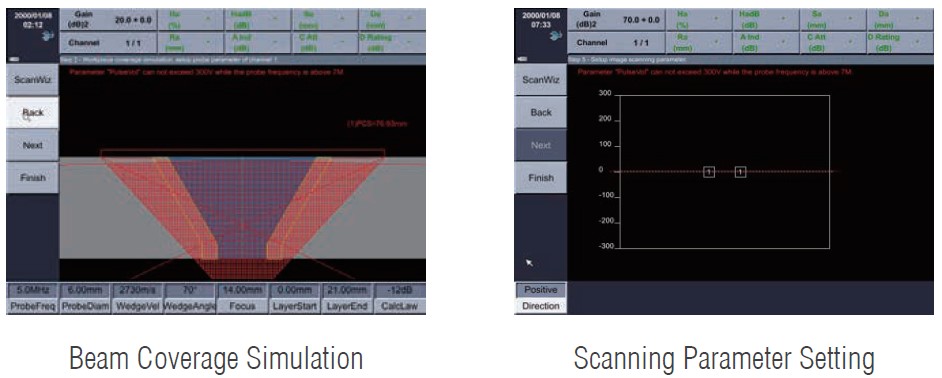

Flat Weld Groove (Flat Plate)

This function is to simulate flat plate work pieces geometry, including the beam coverage simulation and imaging parameter settings.

With this function, it will be easy to analyze, locate flaw signals.

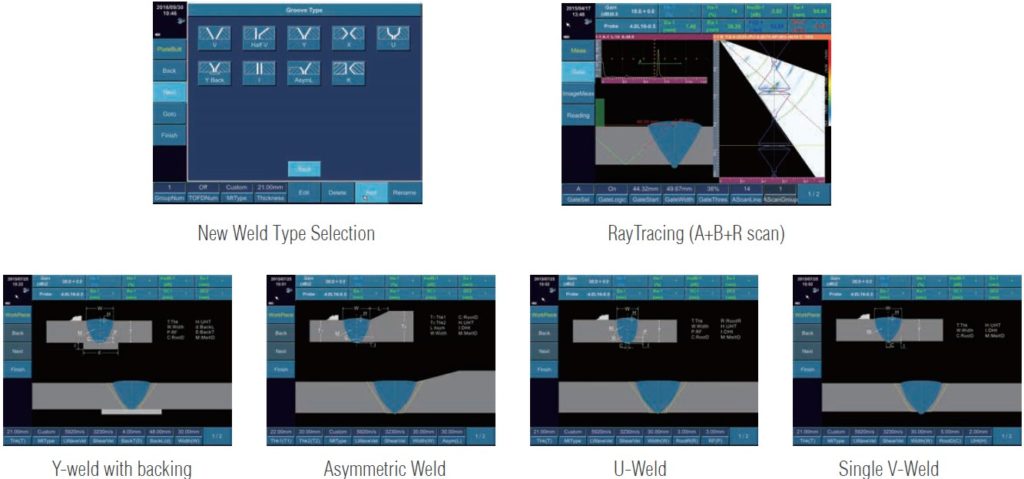

Flat Weld Solution

This solution is suitable for flat butt weld and pipe girth weld inspection.

- Automatically simulate various welds with different grooves types to make simulation closer to the on site weld shape.

- Professional wizard operation mode facilitates operators finish phased array setup.

- Assisted positioning (RayTracing) flaw measurement and report generation functions are available.

- Eight types of weld groove: V, Half V, Y, X, U, I, Y with backing, Asymmetric Welds.

- Quick setup of weld parameters: thickness, material type, groove width, root clearance, up/down reinforcement, fusion simulation, heat-affected zone, as well as workpiece edit, delete, add and rename.

Angle Weld Solution

Suitable for angle welds in ocean platform and oil & gas steel structure.

- Automatically simulate real angle weld shape based on parameters input.

- Simulate sound beam coverage in six different probe positions.

- When RayTracing function is on, the software can auto analyze and judge the workpiece flaw situation, record flaw image and measurement result, and generate test report

Small Pipe Girth Weld Solution

This solution is suitable for testing welds of small diameter pipes with outside diameters ranging from 20.32 – 114.3 mm (0.84 – 4.5 Inch).

By offering features of V-groove and Y-groove weld making, beam coverage simulation, as wee as inserted wedge and link assembly guide table, the solution helps users to finish testing of small diameter pipes quickly.

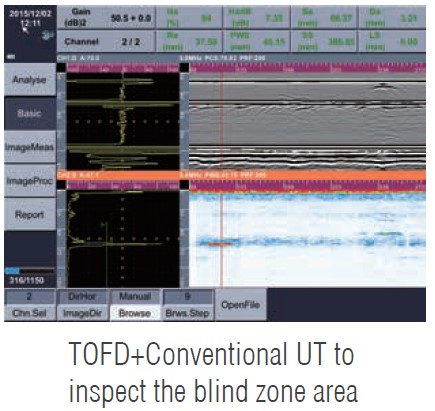

Simultaneous Inspection of PA & TOFD

Simultaneous phased array and TOFD inspection can expand scanning coverage, decrease undetected rate.

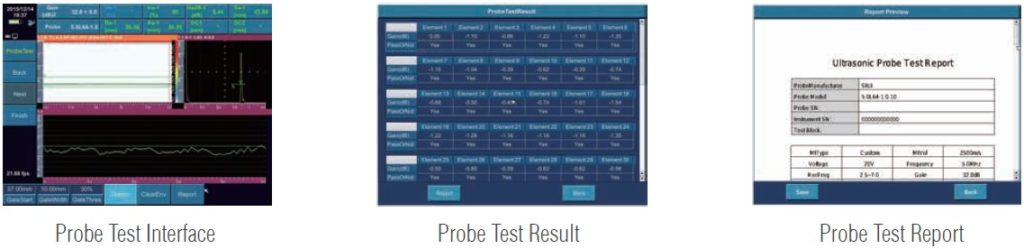

PA Probe Element Testing

Conforming to ASTM E2491 code, this solution achieves auto testing of phased array equipment for its element activity, so as to measure activity of all elements and acoustic energy uniformity of the phased array probe.

Data Source

Corrosion Solution

- Easy to work out scan plan for pipeline corrosion inspection.

- Step by step wizard can guide operators to finish setup easily and improve inspection speed.

- Different thickness will be displayed in different colors, making it easier to determine corrosion situation for pipe.

- Data analysis is available, for better understand the corrosion.

Image Measurement & Report Generation

A-Scan signal waveform and info (angle, south path, amplitude and depth) for any position on the scan figure can be displayed real time, and the operators may use two cross cursors to measure flaw length and height on the B/C/D scans.

The measurement result and flaw images can be saved for generating test report automatically.

TOFD

TOFD Wizard

With step by step menu to guide operators to finish TOFD scanning process easily and improve inspection speed.

Step 1: Setup channel number for inspection.

Step 2: workpiece coverage simulation.

Step 3: Setup wave parameter.

Step 4: Setup encoder parameter.

Step 5: Setup Image scanning parameter

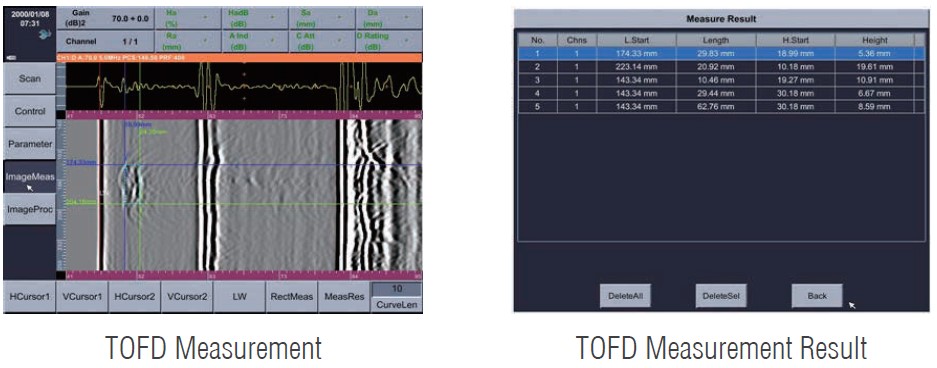

TOFD Measurement

SyncScan TOFD measurement is easy and useful.

The flaw height and length can be measured by moving the reference line. The measurement result is clearly shown in the data table

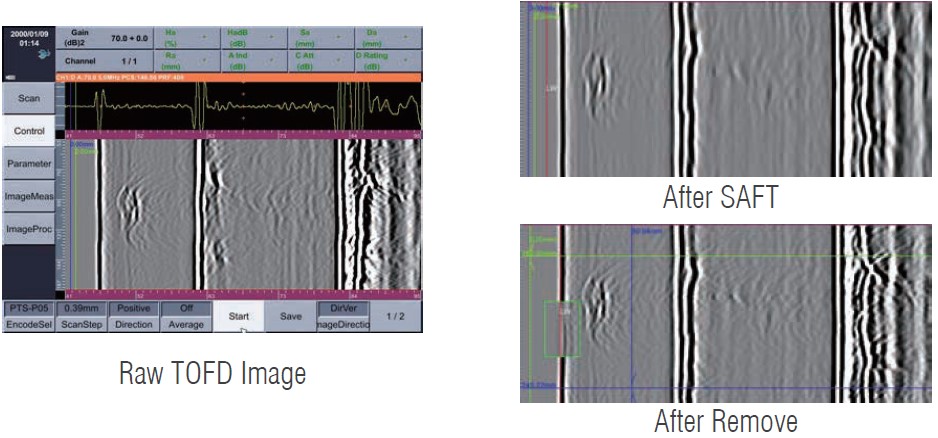

TOFD Image Processing

Perform straightening, filter, local zoom, contrast adjustment, gain post processing and SAFT on the TOFD image.

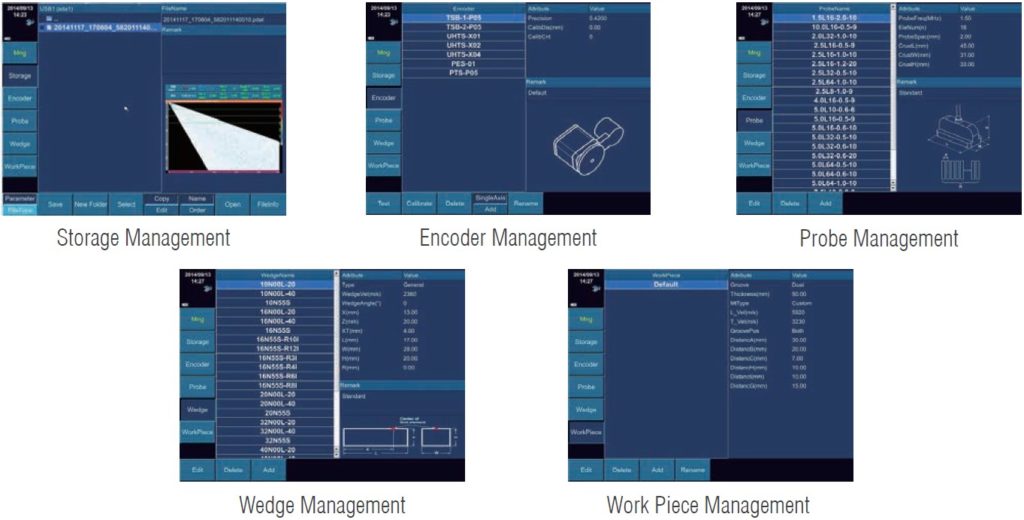

Management

- Easy to use interface to make work piece, probe, wedge, encoder and storage managements more convenient

- In the work piece management, the shape of work piece is simulated and detailed parameters are listed fo reference

- The operator may manage probe and wedge paramater via probe and wedge management

- Follow the wizard, the operator can finish encoder simple operation, calibration and test quickly

- Parameters, screenshot and data can be easly managed in the storage management to enhance the inspection efficiency

PC Software

Main function: Checking data file, Screen capture, Measuring data analysis. Generating test report in word or excel format.

Several files from corrosion solution can be opened and combined. Abundant report samples are available

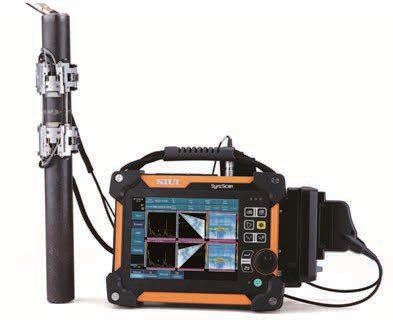

Onsite Application

SyncScan is designed to increase productivity in less demanding application. It is suitable for inspection flaw position and size, which can be widely used for various detection demands, such as PA weld inspection, TOFD weld inspection, corrosion mapping, composite inspection, gas pressure welding on rail, pressure vessel inspection, stainless steel and PE pipe inspection…

PT. NUSANTARA DINAMIKA TECHNOLOGI INDONESIA

(NDTech Indonesia)

PIC: Ir. Pranata Harianto

Mobile: +62 811 987 291

email: [email protected]