with adjustable square wave pulser

- Adjustable spike & Square wave pulser up to 500V

- High resolution display screen with 640×480 pixels

- VGA video output

- Adjustable damping

- Operation frequency up to 20 MHz

- High dustproof & waterproof: IP65 (IP67 as option)

- Optional functions: Network Projection / DAC_JP function / Auto Freeze / Spectrum Display / TCG

Superior Features

- Operating frequency range: 0.5 ~ 20 MHz, highlighting advantages of high sensitivity and broadband.

- Adjustable pulse width square wave transmission is up to 500 V.

- 20 ~ 2000 Hz PRF with 10 steps adjustable: avoid reverberation signals during flaw detection.

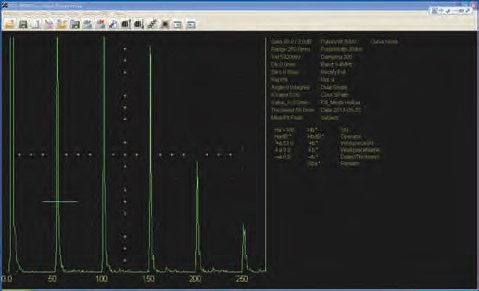

- The convenient and useful probe spectrum analysis function enables the users to know the probe waveform, spectrum and center frequency, resulting in more precise flaw detection evaluation.

- Measure crack height by edge peak echo method.

- Max. sampling rate 240 MHz; Measurement resolution 0.1 mm.

- RF (Radio Frequency) echo display: good to thin-wall material measurement, academic research or qualitative analysis.

- The DAC curve works with echo compare function, making echo quantification of different distances and amplitudes more convenient.

- The AGC (auto gain control) function, together with peak echo and image freeze function, help quickly identify the flaw highest echo, enabling efficient flaw detection.

- Advanced thickness measurement function available.

- Featured with AWS D1.1/D1.5 and API 5UE evaluation standards.

- The gate magnifier function magnifies the echo area within the gate to the whole screen display.

- Up to 500 sets of curve and waveform can be saved for various workpieces and flaw detection standards.

EN-12668-1 and ASTM E317-1 compliant

Application Examples

Ethernet Communication

With network communication, the CTS-9009PLUS can be connected to a PC directly via 100Mbps Ethernet, so as to achieve real-time display and remote control.

Reporting

- Detection echoes, curves or parameters may be losslessly stored to a PC via 100 Mbps Ethernet, facilitating report editing and data management.

- Screenshot and detailed info can be transferred into Microsoft Word for customized reporting.

Typical Applications

The CTS-9009PLUS is designed to increase productivity in various inspection situations.

It is suitable for inspection flaw position and size, which can be widely used for various detection demands, such as pipes and tubes,welding seams, pressure vessels and airplane parts.

Application examples are as follows:

Weld Inspection

- Weld groove profile function

- Peak memory function

- AVG / DGS curve

- Advanced DAC curve

- AWS

Forgings and Casting Inspection

- Adjustable square wave pulser: Up to 500 V pulse voltage

- Manual PRF adjustable:20~2000Hz with 10 steps adjustable

- Peak memory function

- AVG/DGS curve

Thin PLates Inspection

- High operating frequency: 0.5 ~ 20 MHz

- Manual PRF adjustable: 20 ~ 2000 Hz with 10 steps adjustable

- Good near field resolution

- Peak memory function

- AVG / DGS curve

Rail Inspection

- High PRF: Up to 2000 Hz

- Lightweight:The whole unit weight (battery included) is approx. 1.25 kg.

- Peak memory function

- Advanced DAC curve

- AVG / DGS curve

PT. NUSANTARA DINAMIKA TECHNOLOGI INDONESIA

(NDTech Indonesia)

PIC: Ir. Pranata Harianto

Mobile: +62 811 987 291

email: [email protected]