advanced general purpose digital flaw detector

Compact & Portable: The whole unit weight (battery included) is approx 1.15 kg, suitable for aloft and field work.

Easy to Use: There are just a few concisely-defined keys, easy to be operated with only one hand.

Environmental Protection: This system is designed based on IP65 (optional IP67) standard, suitable for complex industrial flaw detection environment.

Super-low Consumption: The configured Li-polymer battery can support up to 7 hours continuous operation.

Strong Performance: High resolution and penetration, achieving precise flaw detection from thin plates to large forged pieces.

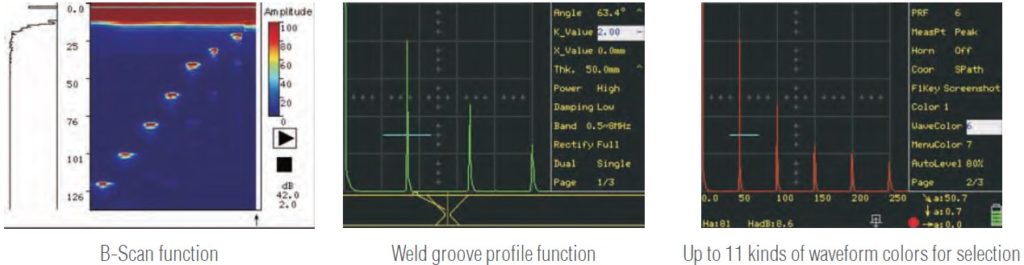

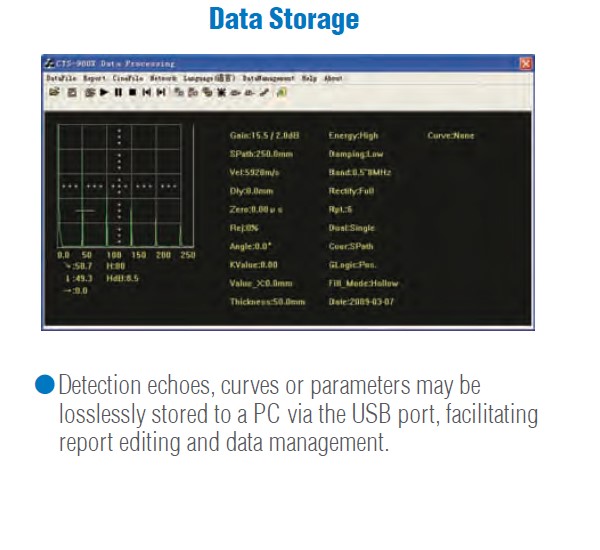

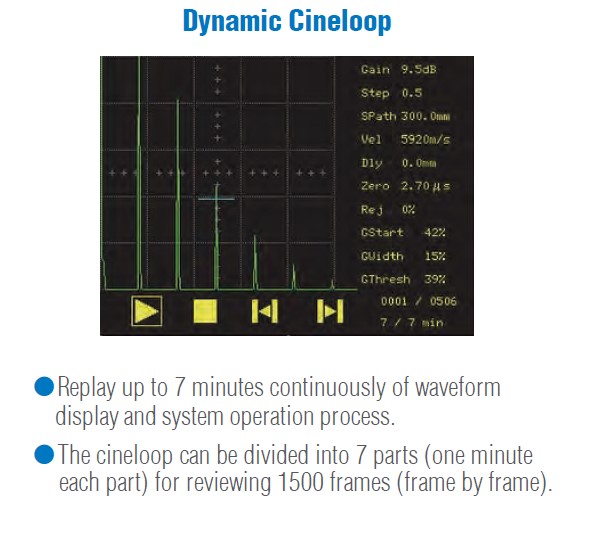

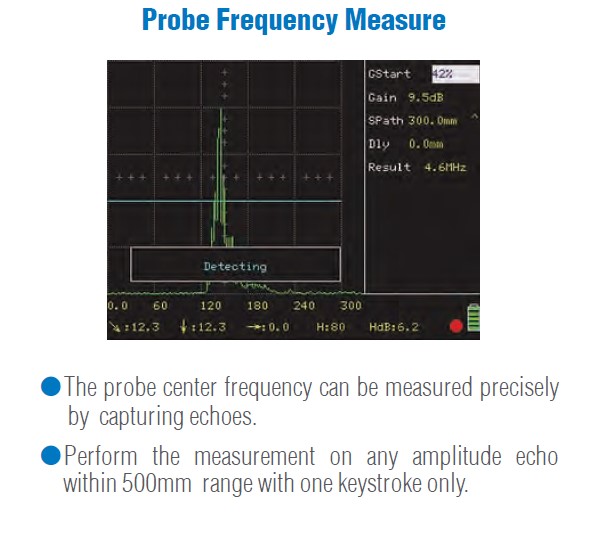

Complete Functions: Cineloop, probe frequency measurement, curved surface correction, RF display, USB storage, amplitude B-scan, AWS D1.1 / D1.5, API 5UE evaluation standard.

Superior Features:

- Max. sampling rate 240 MHz; mesurement resolution 0.1 mm.

- Featured with AWS D1.1 / D1.5 and API 5UE evaluation standards.

- The gate magnifier function magnifies the echo area within the gate to the whole screen display.

- Ethernet communication: Achieving real-time communication with a PC and remote control.

- The convenient and useful probe echo frequency measure function enables the users to know the probe center frequency quickly, resulting in more precise flaw detection evaluation.

- Operating frequency range: 0.5 ~ 15 MHz, highlighting advantages of high sensitivity and broadband.

- 20 ~ 2000 Hz PRF with 10 steps adjustable: avoid reverberation signals during flaw detection.

- Measure crack height by edge peak echo method.

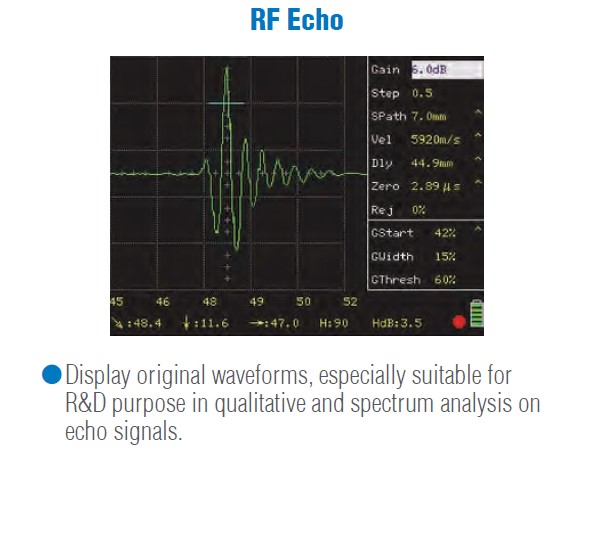

- RF (Radio Frequency) echo display: good to thin-wall material measurement, academic research or qualitative analysis.

- The AGC (Auto Gain Control) function, together with peak echo and image freeze function, help quickly identify the flaw highest echo, enabling efficient flaw detection.

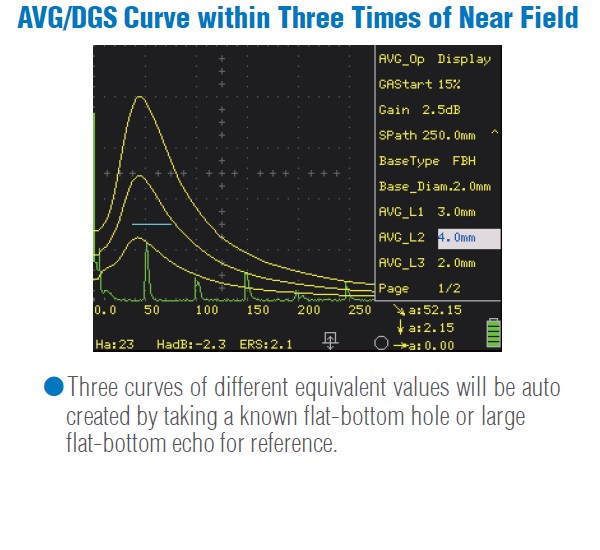

- The DAC curve works with echo compare function, making echo quantification of different distances and amplitudes more convenient.

- Three different color schemes can meet the requirements of different application enviroments and habits.

- Up to 500 sets of curve and waveform can be saved for various workpieces and flaw detection standards.

- Support up to 9 kinds of language.

- Thickness measurement function available

EN-12668-1 compliant

Application Examples

PT. NUSANTARA DINAMIKA TECHNOLOGI INDONESIA

(NDTech Indonesia)

PIC: Ir. Pranata Harianto

Mobile: +62 811 987 291

email: [email protected]