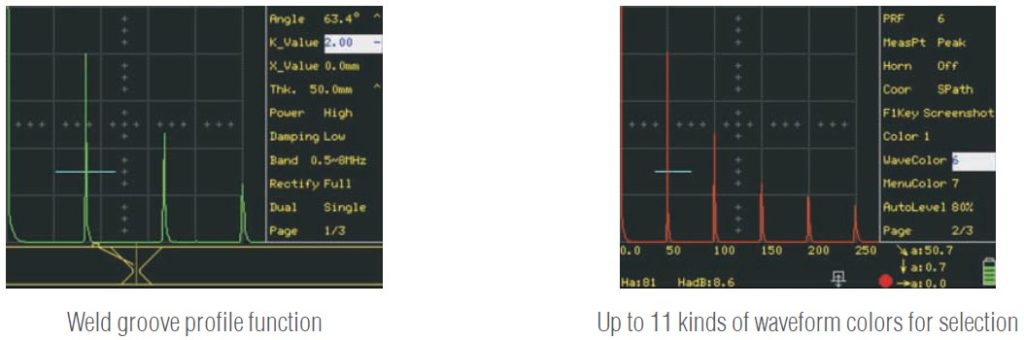

with weld groove profile function

Compact & Portable: The whole unit weight (battery included) is approx 1.2 kg, suitable for aloft and field work.

Easy to Use: There are just few concisely-defined keys, easy to be operated with only one hand.

Enviromental Protection: This system is designed based on IP65 standard, suitable for complex industrial flaw detection enviroment.

Super-low Consumption: The configured Li-polymer battery can support up to 7 hours continuous operation.

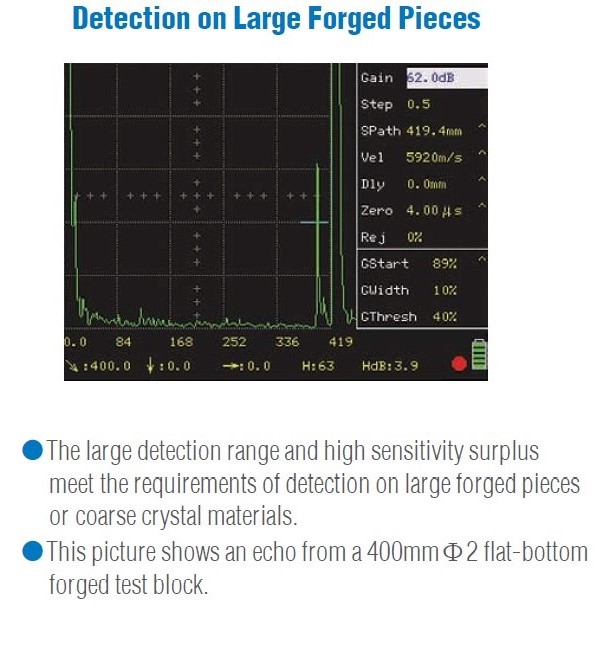

Strong Performance: High resolution and penetration, achieving precise flaw detection from thin plates to large forged pieces.

Superior Features

- Max. sampling rate 240 MHz; Measurement resolution 0.1 mm.

- Operating frequency range: 0.5 ~ 10 MHz.

- 20 ~ 2000 Hz PRF (step: 20 Hz): avoid reverberation signals during flaw detection.

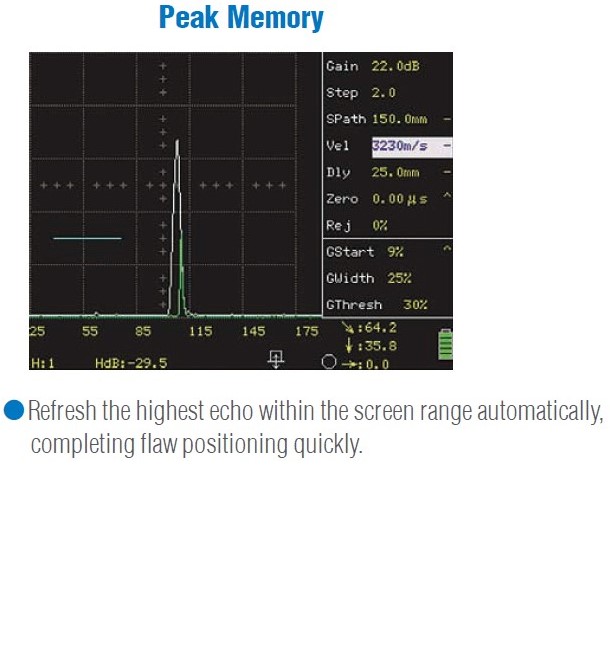

- The AGC (auto gain control) function, together with peak echo and image freeze function, help quickly identify the flaw highest echo, enabling efficient flaw detection.

- The AVG / DGS curve can make three curves of different equivalent values with one known flat-bottom hole or large flat-bottom echo.

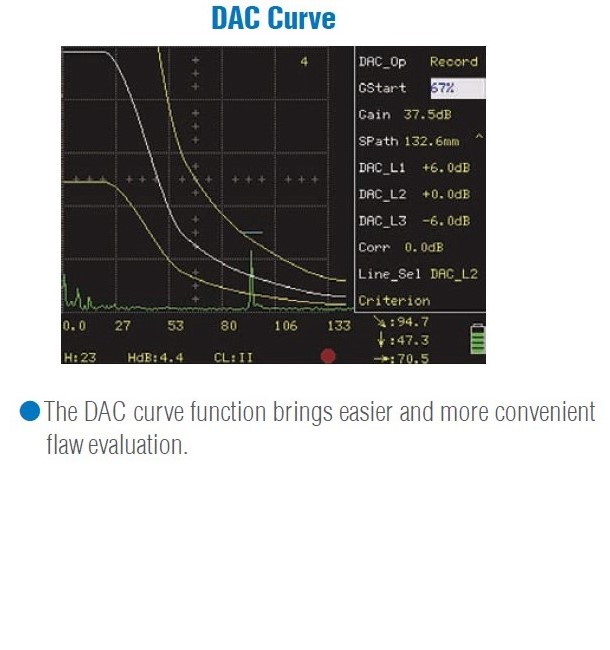

- The DAC curve works with echo compare function, making echo quantification of different distances and amplitudes more convenient.

- The 5.7″ color TFT LCD of wide viewing angle, high brightness and high definition delivers every clear detail.

- Peak memory function facilitates quick scanning and measurement on workpieces.

- Probe angle (K value) measuring function.

- Three different color schemes can meet the requirements of different application environments and habits.

- Up to 300 sets of curve and waveform can be saved for various workpieces and flaw detection standards.

- Support up to 9 kinds of language.

- AWS D1.1 / D1.5, API and TCG functions are optional.

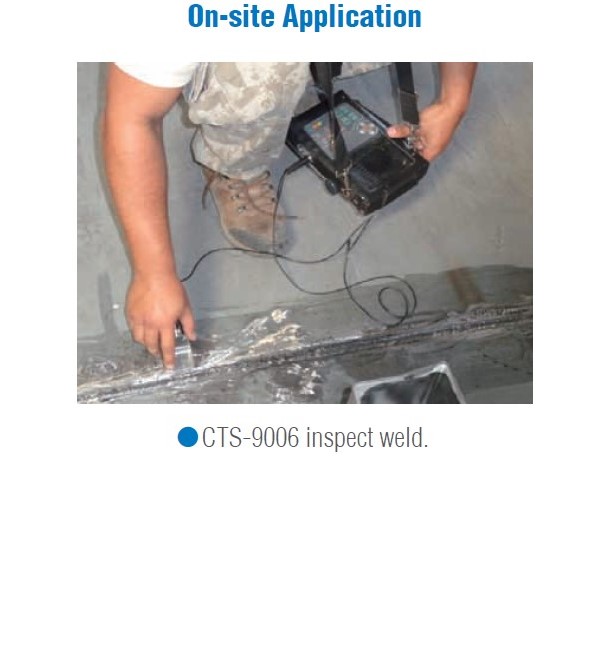

Application Examples

PT. NUSANTARA DINAMIKA TECHNOLOGI INDONESIA

(NDTech Indonesia)

PIC: Ir. Pranata Harianto

Mobile: +62 811 987 291

email: [email protected]