SyncScan 2 is 32:128PR PAUT flaw detector with optional 2-channel TOFD, which can maximize your efficiency for PA and TOFD.

- Light weight: 4 kg only including battery.

- Faster scan speed )approx. 3 meter/minute).

- Removable electric fan: cool down the system when om high temperature.

- 1 or 2 channel TOFD for your selection by license activation.

- Support UT / PA / TOFD, suitable for weld, forging and plate inspection.

- 32 channel PA is more suitable for inspection on extra-thick wall and high-attenuation material.

- 32 channel PA and 2 channel TOFD work simultaneously on pressure vessel inspection (TOFD can measure thickness up to 100 mm).

- Support pitch and catch (PR) mode, corrosion inspection with dual linear array probe.

Overview

Advanced Software

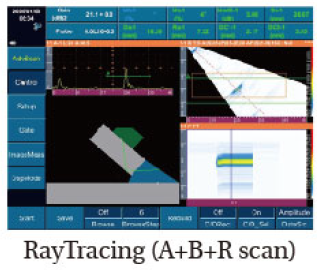

- Multi-view mode helps to locate defects more easily.

- Customized color map to visualize different wall thickness.

- PAUT + TOFD inspection enhances the testing efficiency.

*specific functions are subject to final order.

Suitable for Different Applications

- PA inspection on tube, forged piece, bar, casting, weld, composite material, railway and alloy steel.

- TOFD inspection on weld of plate, pipeline, tank and boiler.

- PA, TOFD and conventional ultrasonic testing in various industries such as transportation, petrochemical, machinery, metallurgy, railway, shipbuilding, aircraft and building.

PAUT Solution for Austenitic Weld

With dual matrix array probe for inspecting austenitic weld in petrochemical and nuclear power industries.

PAUT & TOFD Solution for Long Distance Pipeline

For circumferential weld inspection on long-distance pipeline with OD 1000 – 1300 mm (39.38 – 51.18 inch).

2 PAUT & PAUT+TOFD inspection for selection

PAUT & TOFD Solution for Medium to Large Diameter Pipe

For circumferential weld inspection on medium & large pipes with OD 100 – 1000 mm (3.94 – 39.37 inch) and higher wall thickness.

2 PAUT & PAUT+TOFD inspection for selection.

PAUT or TOFD Solution for Small & Medium Tube Welds

With 16 or 32 elements low-profile PA probes, suitable for girth welds inspection on small tube with OD 20.32 – 114.3 mm (0.84 – 4.5 inch) and medium tube with OD 100 – 300 mm (3.94 – 11.81 inch).

2 PA or TOFD inspection for selection.

PAUT & TOFD Solution for Flat Weld

PAUT Solution for Corrosion

SuporUP PC Software

Checking data file, screen capture, measuring data analysis, playback.

Generating test reports in MS word or excel format.

Several files from corrosion solution can be opened and combined

Abundant report samples are available.

It can be installed in every operator’s laptop without extra cost.

Compatible Crawler

PT. NUSANTARA DINAMIKA TECHNOLOGI INDONESIA

(NDTech Indonesia)

PIC: Ir. Pranata Harianto

Mobile: +62 811 987 291

email: [email protected]